Repair, Reconditioning & Calibration

Repair and reconditioning services are offered for small instruments as well as for microprocessor based instruments for facilitating compliance of statutory norms. Calibration of clients' instruments can be carried out periodically, as per the need. Calibration is traceable to NIST or national calibration agencies. Calibration validates the correctness of data and ensures the credibility of the instruments. These services are provided onsite as well as offsite for all or parts of the system. This is indicated in our calibration certificates.

Consultancy and Related Annual Contracts

iAdept Marketing provides services of measuring analyzing and predicting the machine condition through patented phase angle trending technology vibration analysis / trending (including ground or building vibration) thermal status ultrasonic / acoustic techniques and noise measurement / analysis. Annual Machinery condition monitoring assignments are also taken up besides carrying out machinery fault diagnosis. The company also provides consultancy services for composite condition monitoring requirements and Environmental Impact Analysis (EIA) Studies. The company ensures maximum uptime of your instruments/ machine operations at highly competitive prices . iAdept Marketing provides services of measuring analyzing and predicting the machine condition through patented phase angle trending technology vibration analysis / trending (including ground or building vibration) thermal status ultrasonic / acoustic techniques and noise measurement / analysis. Annual Machinery condition monitoring assignments are also taken up besides carrying out machinery fault diagnosis. The company also provides consultancy services for composite condition monitoring requirements and Environmental Impact Analysis (EIA) Studies. The company ensures maximum uptime of your instruments/ machine operations at highly competitive prices .

Our Services Cover

- Formulating Periodic or 24x7 on line Remote (Internet Enabled) predictive maintenance program for the complete plant using.one of or a mix of.

- Phase Angle diagnostic technology (Patented).

- Vibration Measurement, Frequency Analysis and Diagnosis .

- In-situ Dynamic balancing services.

- Machine train alignment services.

- Suggesting appropriate equipment for predictive maintenance.

- Energy audit services.

- Sound measurement and analysis around machines and in premises.

- Studies of Environmental Impact Assessment due to Vibrations and Noise in Transportation projects including Railway and Metro projects.

- Oil Analysis of lubricants and Hydraulic Fluids for various properties.

- Thermography (Either temperature measuring or thermal imaging) services for equipment.

- Predictive OnlineT: A Multidiscipline Approach.

Specific Benefits of Phase Angle technology

- Phase Angle technology detects fluctuations of motor torque. These fluctuations are caused by mechanical disturbances inside the monitored machine.

The path from mechanical impacts to torque is short and direct.

The same disturbances cause the change of vibration signatures but in this case whole body of monitoring machine is involved. The vibration signatures can be affected by resonance on machine natural frequencies, etc.

- Phase Angle technology can monitor electrical motors AND the machines they drive.

- The PSE footprint is invisible. No diagnostics instrumentation is installed on the monitored equipment. (All diagnostics hardware is located in the electrical cabinet or near it.)

- Many types of disturbances in rotating equipment will be observed earlier by phase angle monitoring than by vibration monitoring. Earlier is better if the time to failure is short. Early detection can avoid emergency shutdowns. Longer lead times of monitoring a disturbance can also lead to more accurate prognostics.

- Phase Angle technology is a type of motor current analysis. Its advantage over other motor current analysis systems is in a patented algorithm which defeats interference from electricity frequency instability and high harmonics.

Vibration Measurement Frequency Analysis and Diagnosis

Vibration analysis can detect developing defects before they cause damages and cause unscheduled downtime. The analysis is part of regular monitoring of machine vibrations either on 24x7 basis or at scheduled intervals. Trending vibration levels helps in detecting problems due to bearing or alignment or looseness or unbalance etc etc. The detection followed by diagnosis and analysis make a composite package, which we offer either for individual element or as package.

We offer these services on one time or once per month or once per quarter basis. These measurements and analysis could be useful in predicting future conditions for foreseeable future of the machines monitored. We offer these services on one time or once per month or once per quarter basis. These measurements and analysis could be useful in predicting future conditions for foreseeable future of the machines monitored.

Besides these services we also offer to arrange corrective maintenance activities for the defects detected through our services of predictive techniques. These could relate to Dynamic Balancing or Machine Train or Shaft / Pulley Alignment. Vibration analysis can help to improve equipment reliability.

We also undetake measurement of Ground Vibrations in machine areas and residential sensitive to such vibrations. The locations could include roof mounted generators, Data centers in large computer dependent facilities, Foundations of high sensitivity and high accuracy machines, Machine clusters having vibrating as well as precision machines, hospitals, multi storey apartments Etc.

Energy Audits and Carbon Management

An Energy Audit is a great tool to optimize energy consumption of any facility. As this is the single largest expense in a plant its optimization means reduction in expenses. Additionally reduced energy consumptions mean lower emissions and healthier environment. For large consumers of energy this could also mean carbon management and achieving carbon neutrality or earning of carbon credits. An Energy Audit is a great tool to optimize energy consumption of any facility. As this is the single largest expense in a plant its optimization means reduction in expenses. Additionally reduced energy consumptions mean lower emissions and healthier environment. For large consumers of energy this could also mean carbon management and achieving carbon neutrality or earning of carbon credits.

Incidentally there are several legislations in many countries now require energy reduction and carbon footprint reduction targets to be met by industry. We help industry in complying with these norms.

We undertake such audits in several stages. The starting point is a walk through audit generating a brief report and concluding part is in the form of full fledged Audit Report. Both reports cover following aspects though the details are covered in brief for walk through audit.

- Plant Summary / Overview

- General Information.

- Energy Conservation Opportunities.

- Utility and Illumination Information

- Hvac Data including heating Cooling Air Handling, Hvac Controls

- Compressed Air Assessment

- Water consumption and utilization information

- Building Envelope Data

- Equipment Repair / Replacement identification and energy savings possibilities

Will cover all HVAC, motors and hot water facilities

- Return on Investment Calculations

Environmental Impact Assessment Studies

for

Vibration and Noise in Rail / Metro and Road Projects

- Ambient Level Measurements

- Noise Levels

- Vibration Levels

- Railway Level Measurements

- Noise Levels

- Vibration Levels

- Road Traffic Noise / Vibration

- Current Noise / Vibration Level

- Estimations

- Predicted impacts of noise & Vib

Oil Analysis of lubricants and Hydraulic Fluids for various properties

We carry out sampling as well as analyzing of oil for various physical or chemical properties as well as materials present in the used oils. The service brings out wear severity as well as contamination levels. We are able to monitor following parameters

| Viscosity |

@ |

40ºC |

and |

100ºC |

| Viscosity |

|

|

|

Index |

| TAN |

(total |

acid |

number) |

|

| TBN |

(total |

base |

number) |

|

| Water Content |

|

|

|

|

Premises and Machine Sound and Noise Analysis

Sound generated by equipment is a great signature for analyzing equipment health and source of abnormalities. In that context we carry out analysis of sound to identify the source of machine problems. We use different kind of sound analysis techniques including Octave analysis. Applications of these techniques is of great relevance in analyzing defects of sealed system like gear boxes and bearings. Sound generated by equipment is a great signature for analyzing equipment health and source of abnormalities. In that context we carry out analysis of sound to identify the source of machine problems. We use different kind of sound analysis techniques including Octave analysis. Applications of these techniques is of great relevance in analyzing defects of sealed system like gear boxes and bearings.

In the context of neighborhood noise we can carry out surveys and provide noise levels present in party halls, open functions, auditoriums etc

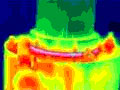

Infrared radiation is emitted by all objects based on their temperatures, therefore, thermography helps to "see" hotspots distinctly. The amount of radiation emitted by an object changes with temperature, therefore thermography allows one to see variations in temperature. The superiority of the technique is due to its ability to cover surfaces instead of linear or point locations. This feature helps in seeing the isotherms and identification of heat change patterns on the surfaces in

Security related applications humans and other warm-blooded animals become easily visible day or night. We can help security agaencies to design appropriate systems for such applications.

Thermal imaging is used many other applications and we obviously provide services in these applications. Applications covered include

Fire Fighting Service - To see through smoke, find persons, and localize the base of a fire.

Predictive Condition Monitoring Service - To locate overheating contacts and parts in plants, which could be potential fire hazards. We can also identify hot areas of mechanical and electrical equipment used in any application thereby helping early rectifications.

Building Diagnostic Service - To detect energy losses in Buildings due to heat leaks affecting cooling or heating of air-conditioning. To identify areas of improper heat balance in complex equipment buildings like data centers.

Plant Assurance Support Service - To help insurance companies carry out pre assessment of plant health in order to fix correct premium against fire for the insurer. This service can also be availed by insurer to get reduction in premium charged

Assistance to Medical Teams - This is a specialized service and details could be obtained from us directly. Plant Assurance Support Service - To help insurance companies carry out pre assessment of plant health in order to fix correct premium against fire for the insurer. This service can also be availed by insurer to get reduction in premium charged

Assistance to Medical Teams - This is a specialized service and details could be obtained from us directly.

Water leakage in pipes up to a depth of 6 meters.

We provide services for tracking water leakage in pipes up to a depth of 6 meters. Our equipment is able to tracing buried utilities and exact finding of their defect locations. These instruments are used for searching leak location, tracing of loaded and dead cables, metal and non-metal pipelines, for accurate temperature and humidity measurement, for energy inspection.

-Detection of power cables under tension, a passive method upto depth of 6m.

We use equipment specially designed for water distribution pipelines We provide services for tracking water leakage in pipes up to a depth of 6 meters. Our equipment is able to tracing buried utilities and exact finding of their defect locations. These instruments are used for searching leak location, tracing of loaded and dead cables, metal and non-metal pipelines, for accurate temperature and humidity measurement, for energy inspection.

-Detection of power cables under tension, a passive method upto depth of 6m.

We use equipment specially designed for water distribution pipelines

Training

Training is provided to clients' staff for using condition monitoring systems as well as specialized systems like environmental vibration & noise monitoring instrument. ISO level training is given on periodic basis or as required. Demonstration models and interactive training CDs are used to supplement the training. Sample content information on Vibration Technology related training programme is provided here.

Training is provided to clients' staff for using condition monitoring systems as well as specialized systems like environmental vibration & noise monitoring instrument. ISO level training is given on periodic basis or as required. Demonstration models and interactive training CDs are used to supplement the training. Sample content information on Vibration Technology related training programme is provided here.

Representative Training Programme Following Category 2/3 of ISO 18436-2,2003 Syllabus and concluded with an exam and generally cover.

- Introduction to Machinery Vibrations

- Definitions,

- Basic Machinery Vibration parameters Period, Frequency, Amplitude

- Data Collection Setup

- Sensors Gear and Bearing Analysis

- Motors, Fans, and Pumps

- Data Processing Analysis of Operating Speed Faults

- Balancing

There are other programmes for vibration technology as below

Three-day programme on Advance Vibration Analysis. The detailed course contents are given in Annexure . Maximum No of Participants in this programme will be 20

Integrated Programme for 5 days covering both options 2 and 3 consecutively.

Completely Computer Based training Following Categoty 2/3 of ISO 18436-2:2003 Syllabus and concluded with

Similar Programmes are available for all diagnostic techniques used by us in consultancy assignments.

Repair, Reconditioning & Calibration

Repair and reconditioning services are offered for small instruments as well as for microprocessor based instruments for facilitating compliance of statutory norms.

Calibration of clients' instruments can be carried out periodically, as per the need. Calibration is traceable to NIST or national calibration agencies. Calibration validates the correctness of data and ensures the credibility of the instruments.

These services are provided onsite as well as offsite for all or parts of the system. This is indicated in our calibration certificates.

Annual Maintenance Contract

In addition to the above services, iAdept Marketing also undertakes annual maintenance contracts. The company ensures maximum uptime of your instruments/ machine operations at highly competitive prices. |